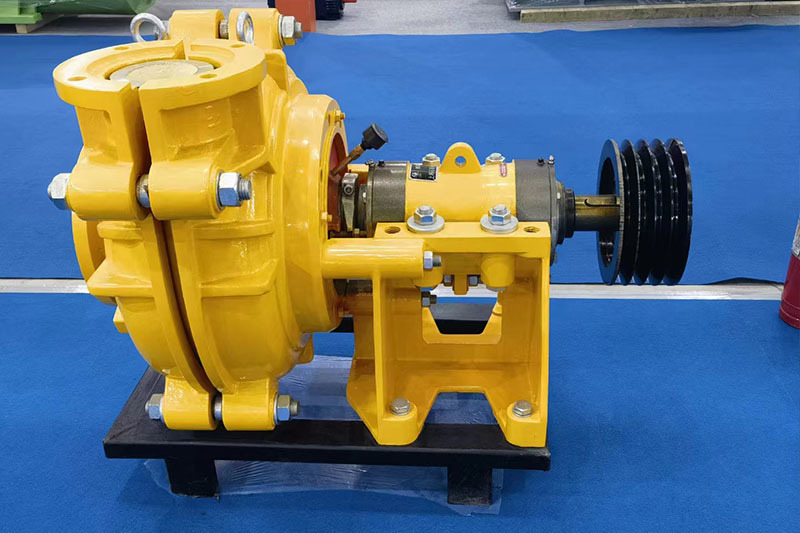

Slurry Pumps Maintenance Tips

Sep 25,2023

Slurry pumps are essential equipment in various industries and play a crucial role in the smooth operation of processes involving abrasive and corrosive materials. To ensure the longevity and efficiency of slurry pumps, proper maintenance is essential. Here are some maintenance tips to consider.

Firstly, regular monitoring and inspection of the pump are necessary. This includes checking for leaks, unusual noises, and vibrations. Any signs of wear and tear should be addressed promptly to prevent further damage. Additionally, inspecting the impeller and casing for any signs of erosion or corrosion is crucial, as these can affect the pump's performance.

Secondly, it is important to maintain the correct operating conditions for the slurry pump. This includes monitoring the pump's speed, flow rate, and pressure. Operating the pump outside the recommended parameters can lead to premature wear and tear and reduce the pump's efficiency. Regularly calibrating and adjusting these parameters can help optimize the pump's performance.

Thirdly, proper lubrication is key to extending the pump's lifespan. Lubricate the bearings and other moving parts regularly as per the manufacturer's guidelines. Choosing the appropriate lubricant and ensuring it is applied correctly can minimize friction and reduce the risk of premature failure.

Furthermore, cleaning the pump regularly is essential to prevent the accumulation of debris and sediment. This can be done by flushing the pump with water or using a high-pressure washer. Removing any built-up material ensures smooth operation and prevents blockages.

Lastly, it is important to have a preventive maintenance plan in place. This includes scheduling regular maintenance tasks, such as replacing worn-out parts, checking seals and gaskets, and performing routine inspections. Adhering to a maintenance schedule can prevent unexpected breakdowns and increase the overall efficiency of the slurry pump.

In conclusion, proper maintenance is crucial for ensuring the longevity and efficiency of slurry pumps. Regular monitoring, maintaining correct operating conditions, lubrication, cleaning, and having a preventive maintenance plan are all important aspects of maintaining these pumps. By following these tips, industries can minimize downtime, reduce operational costs, and extend the lifespan of their slurry pumps.

Key words:

PREVIOUS:

Contact Us

E-mail:

Office Line:

+86 13780213428

Wechat / WhatsApp:

Address:

Shijiazhuang City Luancheng District Xinyuan West Road and Huancheng West Road intersection Tianshan Wanchuang Park 13 production plant No. 13 A